Aerospace Precision in Miniature

The Engineering of Static Model Replicas

Material and Finish

Comprehensive guide to scale aircraft models

Static scale aircraft models are detailed replicas representing military and civil aircraft with high fidelity. The hobby involves disciplines from historical research to fine craftsmanship in kit assembly. These models serve educational and preservation purposes. The objective is capturing form, livery, and technical details, documenting aviation engineering design.

Assembly Processes

Fundamentals of plastic kit construction

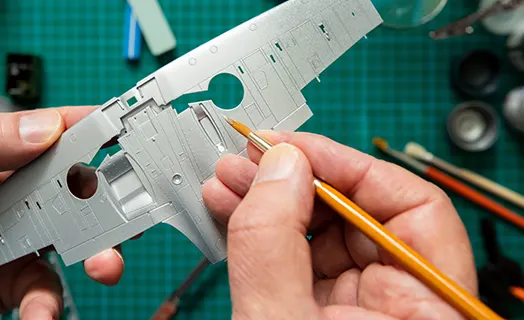

Kit building begins with sprue gate removal and assembling components like fuselage halves. This requires precise alignment using specialized plastic cements. Builders employ dry-fitting to ensure parts align before bonding. Subsequent steps involve sanding seams, filling gaps with putty, and priming the surface for painting.

Material Selection

Properties of materials used in model making

Material choice influences detail and durability. Polystyrene is common for kits due to affordability. Resin captures fine details like panel lines in limited runs. Die-cast metal provides weight for collector models. Photo-etched brass adds realism. Balsa remains a choice for RC flying models due to strength-to-weight ratio.

Presentation Elements

Diorama bases and model display accessories

Display and Environment

Acrylic display cases protect models from dust while allowing unobstructed viewing of the finished build.

Scale replicas of ground support equipment, such as chocks, tow bars, and service carts, can be arranged around the model to create a realistic diorama.

Informational Placards

Custom-engraved nameplates provide information about the aircraft type, operator, and historical context, adding value to the display.

Integrated Lighting

Fiber optic and LED systems highlight cockpit instrumentation, navigation lights, or afterburner details.

Aircraft Anatomy

Key structural components in model representation

Technological integration in modern model design

Modern production uses slide-molding technology for accuracy. CAD software creates blueprints from 3D scans of real airframes. These files guide CNC machining for molds and 3D printing for prototyping or highly detailed aftermarket parts, such as resin engine components.

The role of accuracy in historical replication

Scale model value lies in accuracy, extending beyond proportions to specific squadron livery, precise antennae placement, and ordnance configuration.

Builders prioritize fidelity, turning models into historical documents. Research involves studying archival photos and manuals. The scale, expressed as 1:72 or 1:48, defines the model’s size relative to the prototype, establishing a collection standard. Consistent scales allow direct visual appreciation of different aviation subjects.

Advanced finishing and surface treatments

The final build stage creates realistic surface finishes. This multi-layered process replicates the appearance of operational warbirds or liners.

Airbrushing for smooth color gradients

Double-action airbrushes apply thin acrylic layers, allowing for pre-shading, subtle color modulation, and realistic camouflage patterns.

Decal application for markings and insignia

Waterslide decals replicate nose art, stencils, and complex markings using setting solutions for painted-on looks.

Weathering to simulate operational wear

Oil washes and pigments simulate grease stains, exhaust soot, and chipped paint effects.

The importance of scale in model collecting

Scale ensures collection consistency. Common ratios include 1:144 for airliners, 1:72 and 1:48 for military fighters, and 1:32 for detailed props. Adhering to specific scales enables cohesive dioramas where vehicles and ground crew figures are correctly sized.